EXAMPLES

Explore our collection of sound proofing and thermal insulation examples for various vehicles. Each example provides a description of the steps taken and the materials used, to help you visualise and achieve the same, high quality results.

To find out how much material you will need for a project, the best thing to do is to measure out the areas that you would like to cover. From there, we can help you to calculate how much product is required to achieve your desired outcome.

Vans & Campervans

Door Card

STEP 1

Remove the plastic door card and prepare the surface by cleaning the area using paint thinners or alcohol based cleaners. Do not use white spirits as they leave behind a greasy residue.

STEP 2

For the first layer, 1.5mm sound deadening mats were applied onto the majority of the flat surfaces. For the sound deadening mats to be affective, you must cover at least 50% of the area.

STEP 3

12mm acoustic felt was used for the second layer around the entire surface, in order to achieve the best results. You can add several layers of this material to fill deeper gaps and crevices.

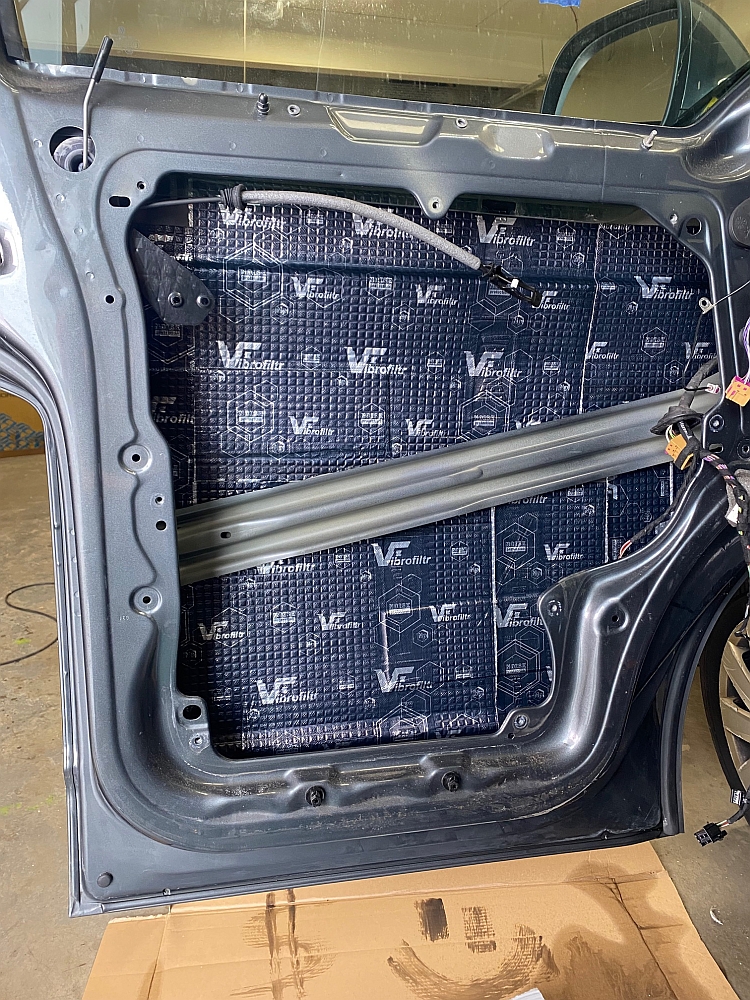

Door Frame

STEP 1

Remove the plastic door card.

STEP 2

Remove the metal partition and raise the window in order to reach the very back of the door.

It is common for this area to be covered with a layer of wax. If that is the case, use paint thinners or alcohol based cleaners to thoroughly clean the area.

STEP 3

For this project, 1.5mm sound deadening mat was applied to the inside of the door. This material helps to reduce vibrations and road noise.

STEP 4

To achieve the best results, a second layer of 6mm ST-mat was applied. This provides both sound and thermal insulation. If you have enough space, you can always use a thicker mat. In general, the thicker the insulation, the better results will be achieved.

STEP 5

Reattach the metal partition.

This area was also covered with 1.5mm sound deadening mat.

Since there was not enough space left, a second layer of ST-mat was not applied here.

STEP 6

Finally, reattach the plastic door card.

Floor

STEP 1

When soundproofing a corrugated floor of a van or camper van, you do not need to apply a layer of sound deadening mats. The corrugated profile helps to eliminate the unwanted vibrations.

When applying thermal insulation to the floor, there are three different methods that you can choose from:

- Apply the thinnest 3mm ST-mat to the entirety of the floor. You cannot use thicker material without additional support! When you add the plywood floor on top of the insulation, the wood will bend as the thicker mat will compress over time.

- If you want to apply thicker insulation, you first must install wooden battens, which will support the plywood floor. You can add the thicker insulation in between the wooden frame and only then attach the plywood floor.

- If you do not want to install battens, but would still like to apply thicker insulation, you can use the method shown below. First, add strips of thicker insulation in between the corrugated ribs (the insulation thickness must match the height of the metal ribs). Then, you can apply the thinnest, 3mm ST-mat, over the entire floor surface.

STEP 2

For this project, the third method was used. 6mm ST-mat was cut into strips and then applied in between the corrugated metal ribs.

STEP 3

Finally, the 3mm ST-mat was applied on top to cover the entirety of the floor.

Wheel Arches & Side Panels

STEP 1

In vans and campervans, most of the road noise comes from the wheel arches and the side panels surrounding them, therefore we recommend using thicker sound deadening mats.

For this project, 2mm sound deadening mats were applied.

STEP 2

For the second layer, 10mm ST-mat was installed inside the side panel.

STEP 3

The 10mm ST-mat was also used to insulate the wheel arches.

Vintage Cars

Under the Bonnet

STEP 1

Clean the metal surface under the bonnet.

STEP 2

Apply our 10mm fire retardant ST-mat. This will provide both sound and thermal insulation.

Be careful when working with this material as the adhesive is very sticky. To achieve the best results, first cut the mat into the shape you will need. Peal off one corner. Stick that corner onto the prepared surface and only then slowly remove the rest of the protective tape.

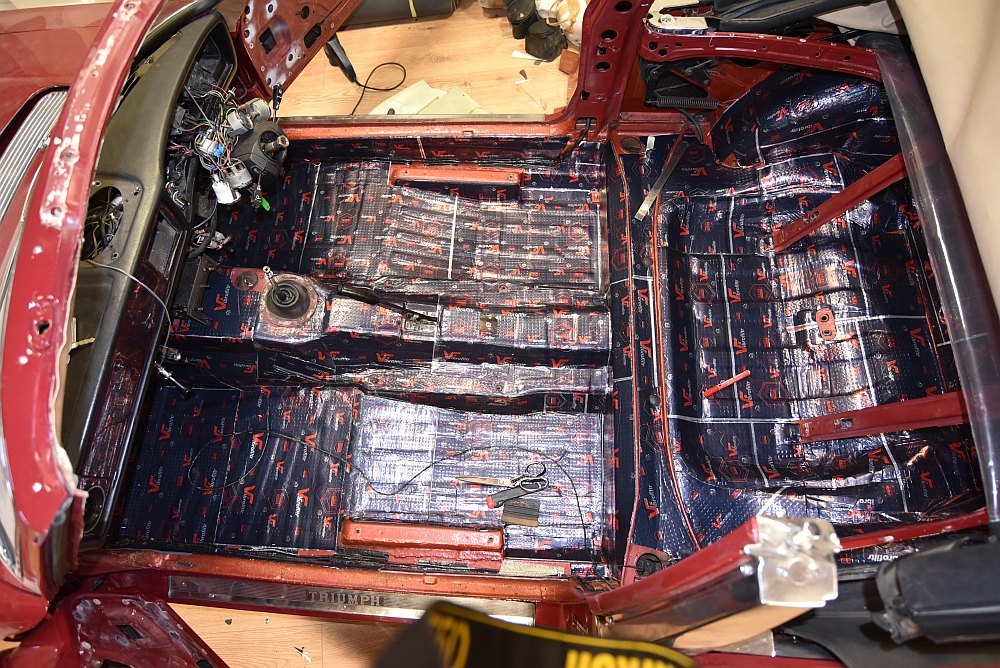

Full Interior

STEP 1

For this project, 4mm sound deadening mats were used to cover the entire floor and the back seat area of this vehicle. This material helps to reduce vibrations and road noise.

Since the floor area for such vehicles is the source of the majority of the unwanted noise, thicker sound deadening mats were used. In general, the thicker the material, the more soundproofing will be achieved. It is also important to keep in mind that sound deadening mats do add additional weight to the vehicle.

STEP 2

For the second layer, 12mm acoustic felt was applied on the back seat area, wheel arches and transmission tunnel. This material helps to absorb high frequency sounds within the vehicle.

8mm PPE ECO mats were applied onto the floor. This material acts as a barrier to prevent further sound from getting into the vehicle, and it can only be applied on flat surfaces.

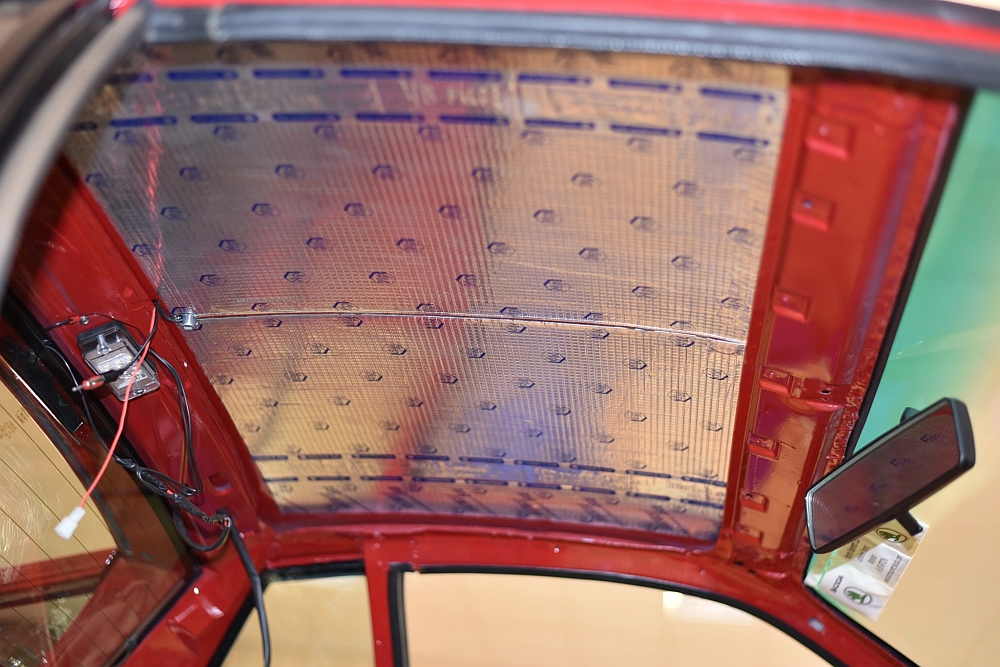

Roof

STEP 1

2mm sound deadening mat was applied onto the roof of this vehicle. Not as much noise is emitted from the roof area, therefore thinner mats can be used.

STEP 2

For the second layer, 8mm acoustic felt was used, to help absorb unwanted sounds.